Company

Screw and Barrel Manufacturing Suppliers

Screw and Barrel Manufacturing Suppliers

INNOVATION AND TECHNOLOGY LEADER, ADVANCED SCREW AND BARREL MANUFACTURER

The consistent philosophy that Nan Yun upholds is ── "Innovative breakthrough, leading technology, insisting on quality

Therefore, Nan Yun continues to design and manufacture high performance, high mixing screws and barrels that competitors cannot produce. After more than 30 years of hard work, Nan Yun has gradually grown at a steady pace and has become a modern manufacturer today. Nan Yun is in the leading position of screw and barrel manufacturers in Taiwan. Looking towards the future , we will always strive hard to pursue higher targets based on our current foundation.

USE QUALITY TO PROMOTE THE BRAND.

USE CREDIBILITY TO ADVANCE THE MARKET.

NAN YUN HAS WHAT NO ONE ELSE DOES!

Super large screw/barrel manufacturing capacity

Nan Yun's design engineers have outstanding theoretical background and practical experience , providing optimum designs of screws and barrels for our customers. Our engineers conduct thorough analysis according to the customer's machine model, production capacity required and resin properties before design. All relates parameters that may affect screw performance are designed based on theorem , such as screw type , L/D ratio , flight depth , flight density , helix angle and so on . This outstanding design capability will ensure Nan Yun's screws and barrels help customers upgrade product quality and production efficiency.

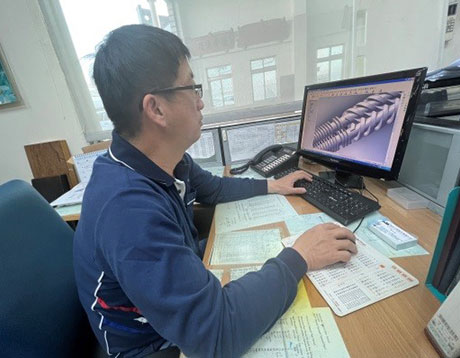

EXCELLENT DESIGN ABILITY--THE INTEGRATION OF THEORY AND EXPERIENCE

The design department of Nan Yun adheres to the professional theoretical basis and rich practical experience to provide customers with the best screw and barrel design. According to the customer's machine type, demand capacity and input raw materials, various parameters include: length-to-diameter ratio(L/D), thread depth, pitch, helix angle, compression ratio, etc., after careful analysis and then based on theoretical basis and Design work with practical experience to ensure that Nan Yun screws and barrels can help customers improve product quality and production efficiency; in addition, as part of the design capability, we also provide reverse engineering services , to provide customers with more competitive options.

VIDEO INTRODUCTION: NAN YUN INDUSTRIAL CO.,LTD - SCREW AND BARREL MANUFACTURING SUPPLIER

Integrated Production Process

Fully Quality Controlled In-house

Over the years, Nan Yun's screws and barrels have been fully satisfactory to all manufacturers of injection molding machinery and extruding machinery both domestically and overseas, and have established a long-term cooperative partnership.

In additional, NAN YUN continually invests in advanced processing equipment and gradually establishing the complete integrated process.

We also adopt the most modern production management to thoroughly control the quality of each step in the process.

In the screw part, from the design, material preparation, quenching and tempering, turning, CNC four-axis tooth profile processing, spray welding on the flights, interior-stress release, polishing, grinding, nitriding heat treatment, hard chrome plating, etc.

In the barrel part, from the design, material preparation, quenching and tempering, boring, interior grinding, turning, milling feeding hole, interior rifle groove, flange drilling, welding, finishing turning, nitriding heat treatment, etc., all these processes are completed consecutively in our company's production line and process arrangement.

The integrated process helps improve operational efficiency, shorten lead times, and we can control the manufacturing quality and reduce the cost to provide customers with high-quality, more competitive screw/barrel.

Precision Processing Equipment. Quality and Accuracy Guarantee

Improving the manufacturing technology of screw/barrel is one of the core strategies of Nan Yun.

Therefore, we continuously invest in advanced processing equipment, such as, deep-hole honing machine, vertical and horizontal CNC four-axis processing equipment, dual-bore barrel processing equipment, PTA spray welding processing equipment, alloy centrifugal processing equipment, rifling machine, wire cutting equipment, etc.

We believe ” It is necessary to have effective tools to do good works.”

Only perfect quality, our customers can make good machines and products, and then achieve a win-win situation and then establish long-term partners relationship.

Excellent Machining ability

Nan Yun's technicians with many years of experience, carefully manufacture each screw and barrel.

100% Quality Inspection

Persistent quality is Nan Yun's tradition

In view of the fact that screws and barrels are the critical components of the extrusion and the injection machine, directly impacting machine performance and the quality of the product.

Therefore, Nan Yun places strict quality control completely for the screws and barrels before leaving the factory.

Our QC Department adopts precision inspection equipment, conducting incoming quality control, in-process and finished product inspection, to ensure that Nan Yun products reach the best quality standard.