News

3 Minutes to Understand Screw and Barrel for Injection Molding, Extruders and Food Processing

3 Minutes to Understand Screw and Barrel for Injection Molding, Extruders and Food Processing

Screws and barrels are essential components in plastic processing machines, including injection molding machines and extruders, as well as in the food processing industry. They are responsible for melting, mixing, and blending raw materials that are then shaped into the desired product. In this article, we will discuss the importance of screws and barrels, the different types and designs available, and how to choose the right screw and barrel for your plastic and food processing machines.

Importance of Screws and Barrels

The screw melts and blends the plastic material, while the barrel is the cylinder that surrounds the screw and is heated to maintain the plastic material's temperature and flowability. When these components work together, they ensure a consistent and uniform melt of the raw materials, which is crucial for the quality of the final product.

Plasticization and uniformity determine the final product's properties, such as strength, elasticity, and impact resistance. Therefore, the screws and barrels' design directly affects the quality and properties of the final product, as well as its color, transparency, and surface smoothness.

Types of Screw and Barrel

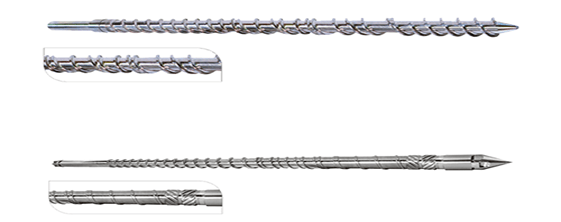

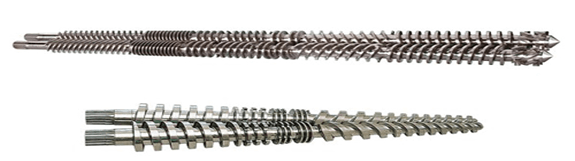

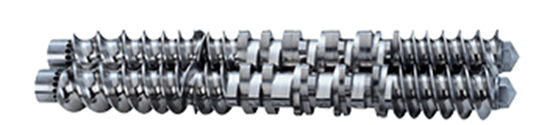

Screws and barrels come in two common types: single and twin. Each type has unique features and advantages, making it crucial to understand their specific applications and differences before choosing the most appropriate screw and barrel for your particular needs.

Single screws and barrels are commonly used in simpler applications with a single input material. Their design is focused on ensuring optimal flow of the material.

On the other hand, twin screws and twin barrels are used to handle a variety of materials and can improve control over blending and melting.

Screws and barrels can also be classified based on their applications in manufacturing processes, including:

- Pelletizing extruder screws/barrels

- Blown film extruder screws/barrels

- Blow molding extruder screws/barrels

- Sheet/Lamination extruder screws/barrels

- Co-rotating twin-screw/twin hole barrel

- Counter-rotating twin-screw/twin-barrel systems

- Injection molding screws/barrels for plastics and rubber

- Static mixing screws

- Single-screw/barrel and co-rotating intermeshing twin-screw/twin-barrel systems for food processing applications

Design of Screw and Barrel

In the plastic and food processing industries, a well-designed screw and barrel can significantly improve production efficiency and quality. During the design process, it is necessary to consider material characteristics, such as viscosity, melting point, and flow rate. The screw and barrel must also be designed to ensure that plastic materials are uniformly melted and blended to avoid overheating and burning. Additionally, it is important to optimize the surface smoothness of the screw and barrel to achieve a balance between material mixing, shearing, and conveying.

To achieve optimal machine performance, it is essential to design screws based on the unique characteristics of each plastic material.

Improperly designed screws and barrels will lead to increased defect rates, equipment malfunctions, and higher operating costs. It's essential to provide your screw and barrel manufacturer with critical information regarding your raw materials, machine conditions (such as horsepower, maximum speed, etc.), expected production output, desired lifespan, and other specifications. Manufacturers with rich design experience, they can evaluate the feasibility according to your needs, provide tailor-made design suggestions, and use their production technology to manufacture high-quality, long-life screws & barrels to optimize your production process, and get the best production efficiency and quality!

Nan Yun is proud to offer a strong design team, along with top-notch process planning and precise processing capabilities( factory tour video ). This winning combination allows us to improve the production capacity and service life of screw barrels, maximizing the mechanical capabilities already in place. We also offer reverse engineering services, including measuring and refurbishing old products, or implementing design changes to existing products. This provides our customers with a range of competitive options to choose from.

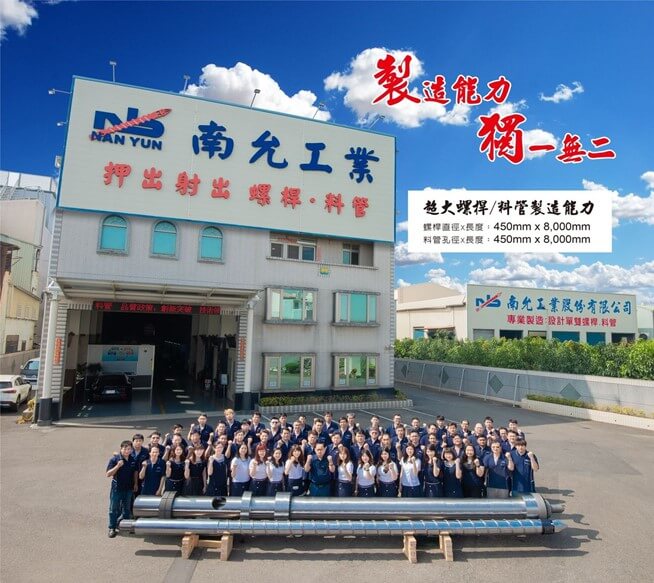

Nan Yun: A Global Leader in Screws and Barrels Manufacturing

Nan Yun has extensive experience in manufacturing high-output, long-lasting screws and barrels, and places great emphasis on the quality. As the leader in the production of screws and barrels for the last 30 years(factory tour video), we continuously invest in advanced equipment to ensure consistent processes that comply with high quality requirements. Leveraging our expertise, we produce screws and barrels that satisfy our customers' unique applications.

Our professional design team meticulously evaluates customer requirements and suggests the best materials and processes for screw barrel production. At the core of everything we do at Nan Yun is a commitment to quality and customer satisfaction. Our extensive production technology experience guarantees that the screws and barrels we produce meet customers' expectations for performance, durability, and efficiency.

To provide our customers with the most comprehensive services possible, Nan Yun has invested in refurbishment equipment. This enables us to refurbish old screws and barrels, which extends the service life of our customers' machinery and products, resulting in significant economic benefits. While the profit margin for repairing old products is not high, few manufacturers are willing to invest in the necessary equipment to provide this service. By choosing Nan Yun, our customers can benefit from our expertise and receive the most complete advice and service available.

Whether you require more efficient screws and barrels for your plastic processing or food processing machines, or need to replicate a sample product, Nan Yun has the expertise and experience to meet your needs. If you have any further questions about screws and barrels, please don't hesitate to contact our team, and we will gladly assist you.