Products

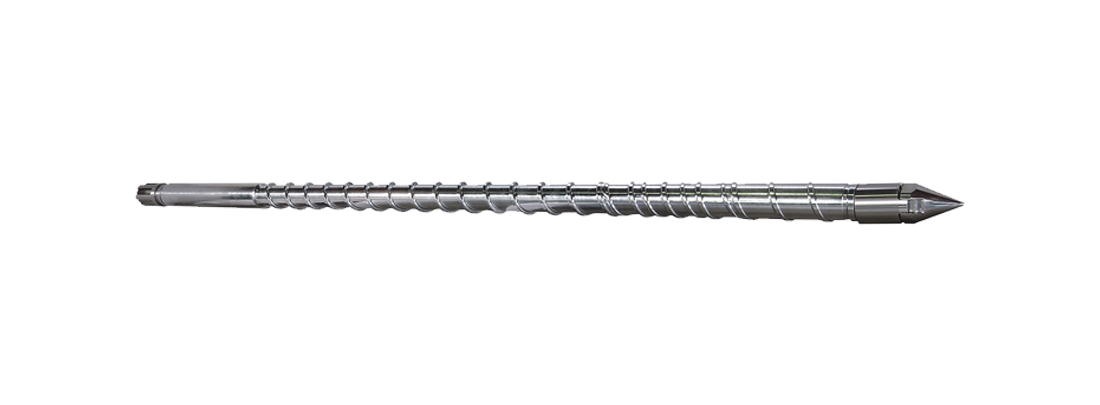

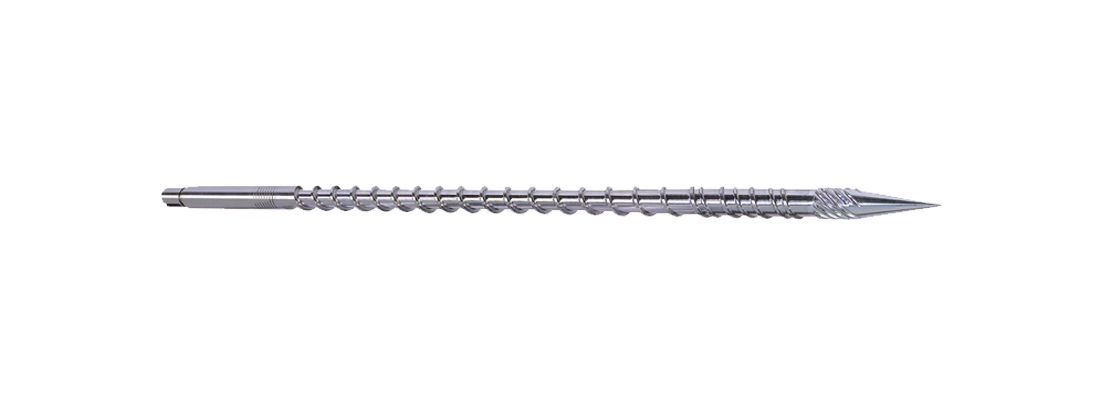

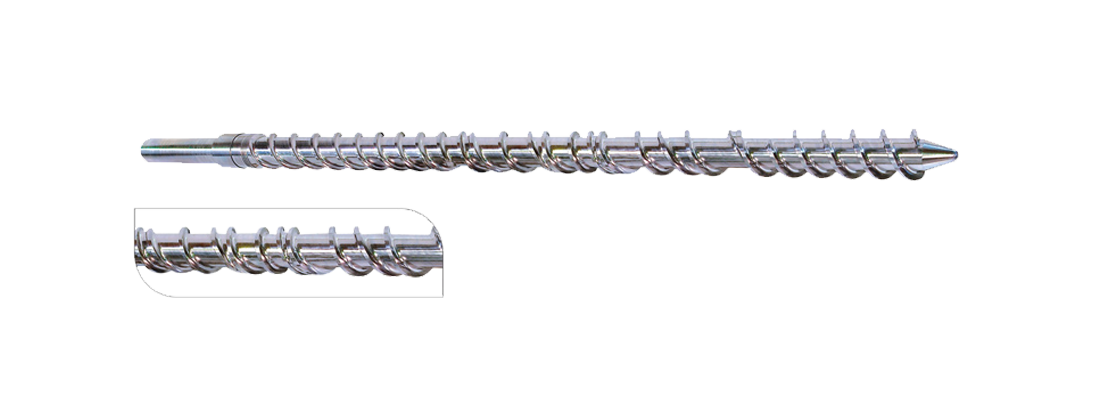

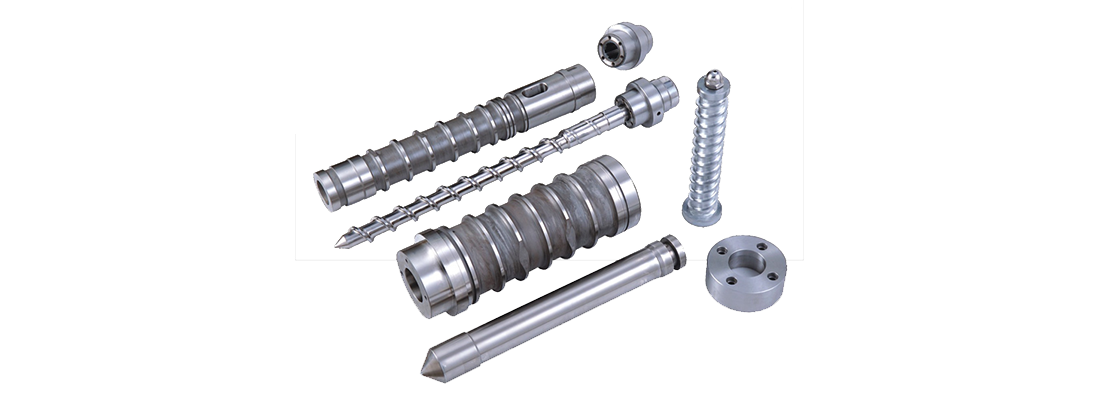

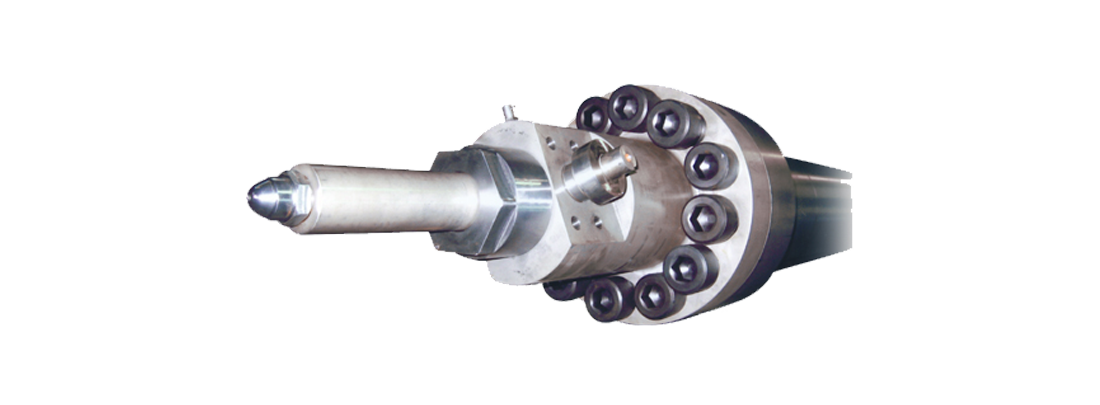

Single Screw and Barrel for Plastic Injection Molding

Single Screw and Barrel for Plastic Injection Molding

Importance of Screw and Barrel in Plastic Injection Molding

The screw and barrel are essential components of the injection molding machine. They work together to melt, mix, and transport the plastic material from the hopper to the mold cavity. The primary function of the screw is to generate the necessary pressure and heat to melt the plastic pellets. The barrel, on the other hand, provides the containment and the environment for efficient melting and homogenization of the material.

Screw Functionality

The screw in an injection molding machine is responsible for three main functions: plasticizing, homogenizing, and injecting the molten material into the mold. The plasticizing process involves melting the solid plastic pellets by applying heat and pressure along the length of the screw. As the screw rotates, it transports the molten plastic material toward the front end of the barrel, where it becomes homogenized and free of any air or gas bubbles. Finally, the screw injects the molten plastic into the mold cavity with precise control over the speed and pressure.

Barrel Functionality

The barrel provides the necessary containment for the screw and ensures optimal heat transfer to the plastic material. It is equipped with heating elements that maintain the required temperature for melting the plastic pellets. The barrel also plays a crucial role in the homogenization process, as it allows for thorough mixing and removal of any inconsistencies in the molten plastic. Additionally, the barrel provides the necessary pressure to push the molten plastic material through the nozzle and into the mold.

Benefits of Using High-Quality Screw and Barrel

Using high-quality screw and barrel components in injection molding offers several advantages:

- Improved Processing Efficiency: High-quality screws and barrels ensure efficient melting, mixing, and homogenization of the plastic material. This results in smoother processing, shorter cycle times, and increased production efficiency. Additionally, precise control over melt temperature and pressure allows for consistent part quality and dimensional accuracy.

- Enhanced Product Quality: The use of high-quality screw and barrel components contributes to improved product quality. The thorough melting and homogenization of the plastic material reduce the presence of defects such as air pockets, color streaks, or inconsistent melt flow. This leads to visually appealing, structurally sound, and dimensionally accurate final products.

- Extended Machine Life: Investing in high-quality screw and barrel components can significantly extend the life of the injection molding machine. The use of durable materials and precise manufacturing processes ensures reliable performance, reducing the risk of premature wear or failure. This results in reduced maintenance costs, increased uptime, and prolonged machine longevity.

Screws and barrels are integral components of the injection molding process, playing a crucial role in achieving optimal melt quality, homogeneity, and part consistency. Investing in high-quality components and following proper troubleshooting steps can lead to improved production efficiency, enhanced product quality, and extended machine life. If you have any needs or questions about screws and barrels for plastic injection molding, welcome to contact us!

| Length | Circularity | Straightness |

|---|---|---|

| 50~1,000 mm | 0.005 mm | 0.005 mm |

| 1,000~2,000 mm | 0.01 mm | 0.01 mm |

| 2,000~4,000 mm | 0.015 mm | 0.015 mm |

| 4,000~6,000 mm | 0.02 mm | 0.02 mm |

| 6,000~8,000 mm | 0.03 mm | 0.03 mm |